Post Event Report

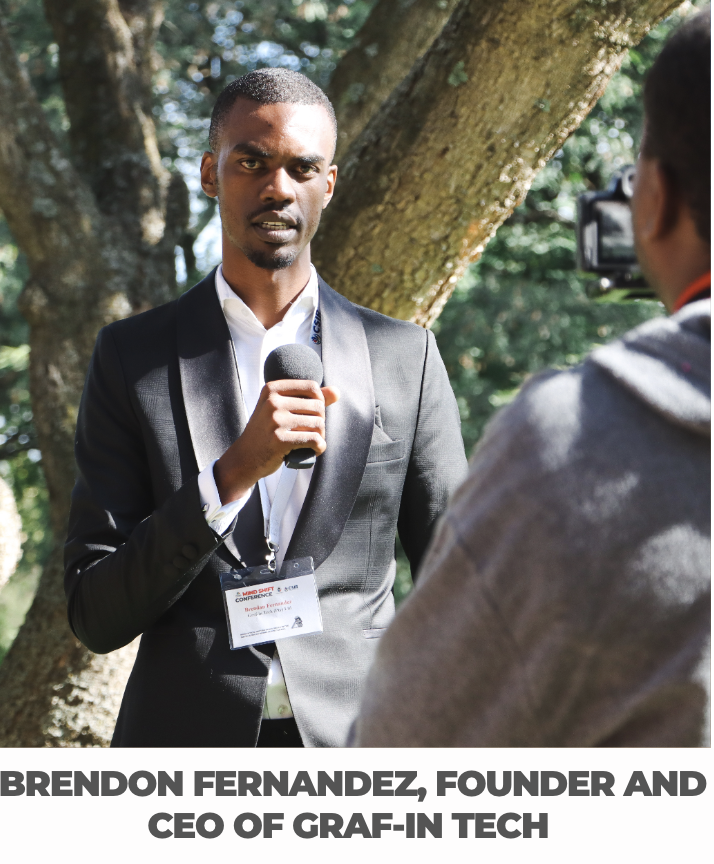

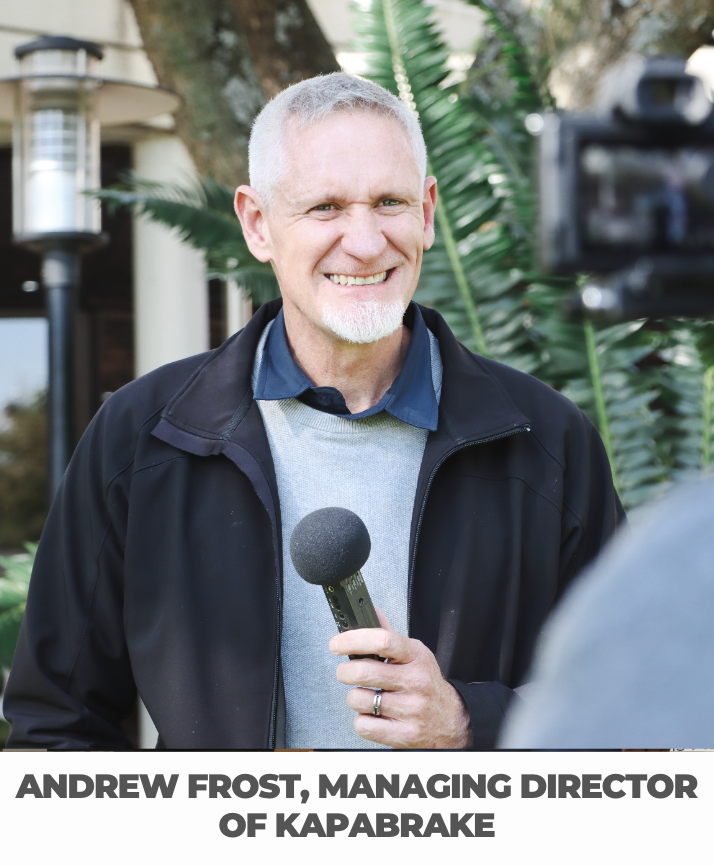

Innovation, Digitisation & Skills in the South African Mining Supply Chain was the theme of the recently held MEMSA Mind Shift Conference, held in at the IDC in Johannesburg recently. The event was aimed at facilitating new technologies and partnerships to ensure the sustainability of the South African mining supply chain and the mining industry as a whole. The 2023 Mind Shift Conference drew together a wide range of stakeholders from the mining industry supply chain, research institutions, the skills sector and government to build a shared understanding of challenges, opportunities and strategies for succeeding together.

The conference was coupled with the second editions of the Manufacturing Excellence and the Innovation for Mining Awards aimed at showcasing, publicising and driving innovation in the South African mining supply chain, and ultimately driving competitiveness in the sector. The winners of which received high praise from Mr. Sietse van der Woude, Senior Executive: Modernisation and Safety at Minerals Council of South Africa, who was impressed with the quality of the equipment manufacturing companies and their products and who was quoted as saying 'it takes real bravery to be an entrepreneur and an innovator'.

Alignment of regulations and legislation to create greater certainty and a supportive environment, could stimulate greater innovation. In addition to the innovation for mining awards winners there are currently excellent examples of the strength of innovation in the sector that speak to these new technologies.

The Hydro Power Equipment (HPE) Maxi Bolter and PP3 power pack provide a safe, fast, environmentally friendly, water wise, and complete roof bolting solution which can be operated remotely via umbilical controls. The power pack delivers high pressure water to operate three maxi bolters in a typical bord & pillar mining section and can be transported via utility vehicle cassette.

Energy Densification Systems (EDS) have designed a compact vertical Multi-Shaft Mill utilising high-speed impacts to break down particles with large reduction ratios, low energy consumption and improved liberation compared to traditional milling methods.

Multotec's Pulping Chute scrubs ore material in a carrier liquid. Through the innovative use of slurry deflectors, calibrated turbulence and reverse flows are created, improving the efficacy of scrubbing and laundering actions.

SME Khentsa Steel havedeveloped a tube pressure testing device, which will aid the seam welded tube industry to ensure the safety and integrity of products such as lancing tubes which are used in for mineral processing.

GR Mining has reduced the time and cost involved in commissioning underground refuge bays, by designing collapsible, easy to erect and legally compliant emergency toilets. Their vent trapdoor is designed to open automatically and improve airflow when dangerous levels of methane are detected.

In terms of digital solutions for mining, Riis worked with consortium partners to develop two innovative applications. The first supports SMEs through the process of qualifying as vendors with local mines; the while the second allows mines to assess digital leadership capabilities amongst its workforce.

In the South African context new technologies do not need to replace employment by mines, but can enhance human decision making and safety, and machines can be sent into depths and areas too risky for human operators and by manufacturing equipment locally, quality jobs are created in manufacturing.

Collaboration remains key, and Mining Equipment Manufacturers of SA (MEMSA), a member-based cluster together with a wide range of innovation partners such as the Mandela Mining Precinct is helping to drive innovation and competitiveness in the local mining equipment manufacturing industry through activities such as the first Mind Shift Conference and facilitating technology development partnerships.

The feedback from delegates has been overwhelmingly positive; one participant reported, 'Words cannot describe the impact of this event'.

We would like to sincerely thank our expert speakers and panelists, who took time out of busy schedules to address the conference and engage in lively discussions. The feedback from delegates has been overwhelmingly positive; one participant reported, 'Words cannot describe the impact of this event' .

Day 1. Speakers & Presentations

- The Digital Factory has Arrived Johan du Toit - Syspro

- Digital Logistics Management, Scan Global

- Assembling Capacity - Application of assembly systems in South Africa, Tapiwa Samanga, PtSA

- Developing and Sharing Manufacturing Technology, Dr. Ajith Gopal, CSIR

- 4IR, Employment and work – Report on a seminar with union leadership, Tebogo Mdhluli, NextGenEx

- Building skills for Manufacturing 4.0, Gideon Potgieter, Resolution Circle

Day 2. Speakers & Presentations

- Ten Insights into 4IR Jean-Jacques (JJ) Verhaeghe, Programme Manager: Minerals Council South Africa | Mandela Mining Precinct at Minerals Council of South Africa

- The Mining Innovation Ecosystem Lithakazi Nxiweni, RiiS

- Innovation in Digital Technologies M Ahsan Mahboob, Wits Digimine

- Connecting Science and the Mining Industry Sibongile Ntsoelengoe, CSIR

- Innovation Processes Dr. Maje Phasha, Mintek

A warm thank you to our sponsors, without whose support this event would not have been possible:

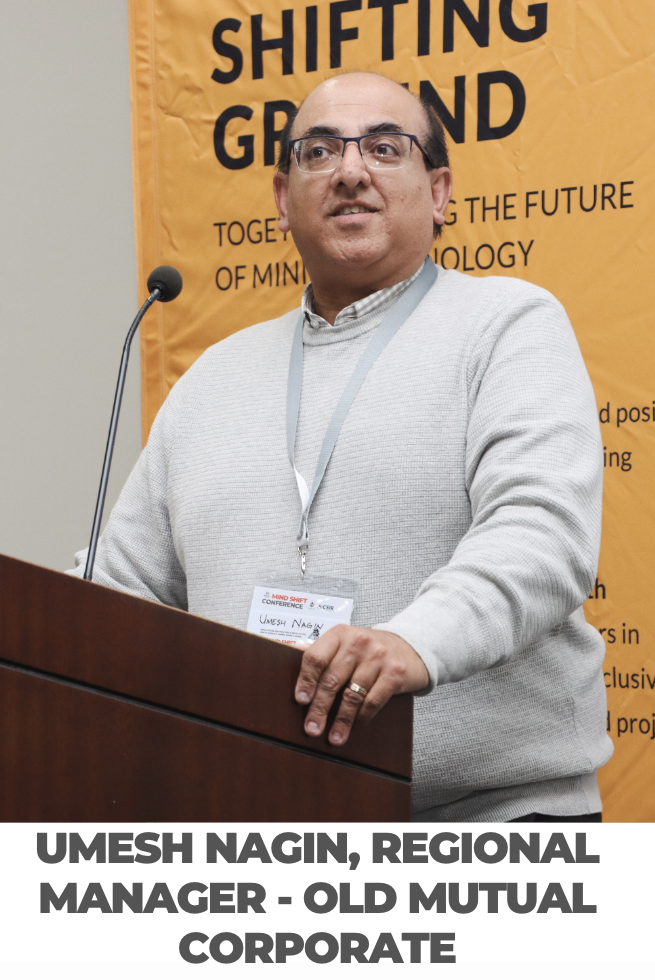

Old Mutual - Conference Sponsor:

Syspro - Manufacturing Excellence Award Sponsor

ScanGlobal Logistics - Networking Cocktail Dinner

HydroPower Equipment (HPE) - Water Sponsor

Council of Scientific & Industrial Research (CSIR) - Lanyard & Name Tag Sponsor

And most especially thank you to The South African Minerals, Extraction, Research, Development and Innovation (SAMERDI) initiative, a unique collaboration between the mining industry and government, and the main sponsor of the Mind Shift Conference, and the Innovation for Mining and Manufacturing Excellence Awards.

We have learned a lot during the course of the planning and execution of the conference and look forward to our second event in 2024.