2024 Post Event Report - Mind Shift Conference

MEMSA Mind Shift 2024 Innovation, Digital Technology and Skills in the SA Mining Supply Chain, aptly themed 'Smart Solutions for People and Planet', brought together experts and thought leaders from the mining industry to share insights and advancements in technology that drive safety, sustainability and efficiency.

The 2024 Mind Shift Conference, themed 'Smart Solutions for People and Planet', emphasised collaborative innovation in the mining sector by bringing together a diverse array of stakeholders. Speakers and panellists included representatives from the mining industry, supply chain, research institutions, the skills sector, and government. The conference aimed to address critical issues such as human safety and well-being, the environmental and socio-economic impacts of mining, and the integration of new digital tools that enhance mining capabilities.

Why a Mind Shift?

By fostering a "Mind Shift" towards new goals, the conference aimed to reimagine the minerals industry, emphasising the importance of local entrepreneurship and innovation in achieving sustainable and technologically advanced mining practices. This requires a shift towards developing solutions to enhance worker safety and health, ensuring that mining practices are not only efficient but also safe for all involved. Addressing the ecological footprint of mining activities and promoting sustainable practices that minimise environmental degradation. Exploring ways to ensure that mining activities contribute positively to local communities, create economic opportunities and improve living standards. The conference highlighted how digital tools such as AI, IoT, and big data are transforming the mining industry, making operations more efficient, safer, and more sustainable, and how through encouraging multidisciplinary and multi-stakeholder collaboration, involving entrepreneurs, inventors, engineers, manufacturers, researchers, and investors we can foster innovative solutions and new opportunities in the mining sector.

Read the Engineering News & Mining Weekly article HERE

Beeuwen Gerritts, Chief Director of Department of Science and Innovation opened the 2024 Mind Shift Conference by reminded us progress cannot be furthered in isolation. We require 'incremental innovation', working daily on being better, faster, safer and more competitive. We need 'disruptive innovation' through being cheaper or more accessible, and lastly 'creative innovation' in product and processes which increase productivity through replacing old norms with new efficiencies.

Professor Glen Nwaila, Wits Mining Institute, then lead us through an insightful presentation on Innovation in a Time of AI "As the world moves to using AI, the importance of emerging technology requirements for green energy for the future and zero harm for people and the environment becomes a priority" and reflected on the difference between novelty and innovation.

The panel discussion Putting our Heads Together: Collaboration for Innovation moderated by Bokang Kalepa, Baletsema featured experienced leaders in technology development for safety, Dushendra Naidoo, Head of Safety and Sustainable Development MCSA, Dr. Adwoa Issaka, Unit Manager Safety at Gold Fields, Pogiso Mthimunye, Innovation Lead, Operations at Exxaro and Fleckson Magweregwede Centre of Excellence Manager at Mine Health and Safety Council.

According to Mr. Naidoo"Technology adoption needs to be holistic; proper skills and training, and a people-centric approach to safety. This will require diversified micro and macro collaboration between stakeholders, generating solutions". He also supports the idea of a localisation campaign where competitors can come together to do the necessary work now, to embrace technology.

The collaborative innovation sandbox session facilitated by Julie Courtnage, Executive Director, Mandela Mining Precinct engaged the audience in developing collaborative technological innovations and processes for the mining industry. "Do not let perfection hamper progress."

Louw Steyn, from patent law firm and sponsors of the Innovation Awards, Spoor and Fisher gave an excellent presentation on IP Protection in Collaboration.

The day ended with the Gauteng: Province of Innovators Cocktail Networking evening overlooking the Johannesburg skyline sponsored by the Gauteng Growth and Development Agency (GGDA).

The Innovation for Mining Awards, the only innovation awards for the mining sector in South Africa aimed specifically at local companies and local IP was again a highlight of the Mind Shift Conference.

As in 2023, this years' awards were categorised by equipment type and included, Innovation in Hard Rock Mining (The Navin Singh Award), Innovation in Soft Rock Mining, Innovation in Surface Mining, and Digital Solutions for Mining.

This year we expanded the thematic awards, to include exciting new categories in line with the Conference themes; Innovation for an Energy Transition recognising innovations which reduce the use of carbon fuels or which support the transition to Green Energy, Innovation towards Zero Harm for innovations in support of mining which is safer and reduces health impacts of mining and Innovation by an SME recognising the fact that our SMEs are highly innovative.

Two completely new categories highlighting the growing use of data, and importance of collaboration in a complex tech landscape and global industry; Innovative use of Data and Collaboration for Innovation, offering our members and the wider industry with exciting opportunities to showcase their achievements, and inspiration to keep pushing the boundaries.

The first three award winners were announced, and winners were invited on stage to share their journey.

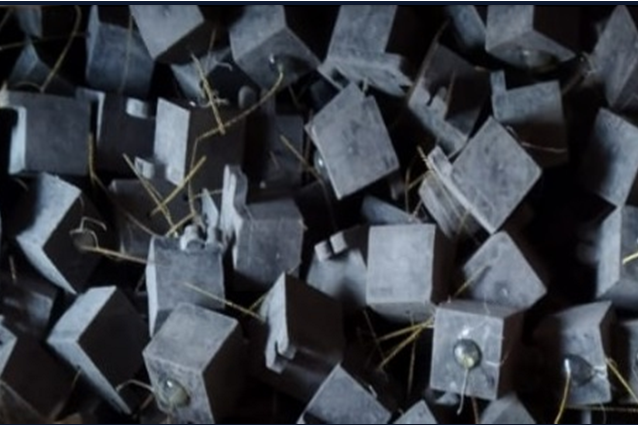

Simera Trace's Digital Ore Identification and Tracking System offers a blast resistant smart sensor block that mimics the behaviour of specific ore. During blasting the smart tracers shift with the ore and create a digital trail. Data is captured to a software platform enabling the optimisation of ore grade control and processing performance. Simera Trace is training and empowering local, rural-based black owned companies as service providers to mines.

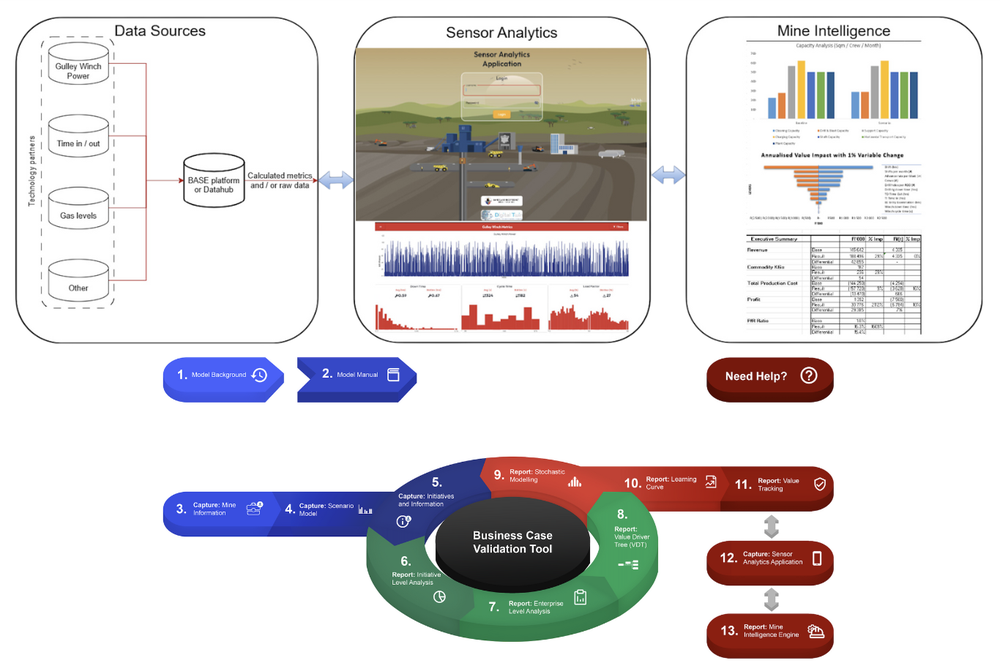

The Digital Business Case Evaluation and Tracking Tool including Mine Intelligence Engine and Sensor Analytics Application (DX BC Tool) uses Excel for calculations and reporting while the app tracks the performance of implemented initiatives against expected benefits. The web-based sensor analytics platform ingests, stores, analyses and displays data, providing digital initiative evaluation (financial/non-financial) at the mine or across several mines.

Gravitas Minerals Coal Recovery Processes, a three-year collaboration with Fraser Alexander culminated in SuperMag technology which extracts product from tailings thereby increasing the life of the discard dump and tailings pond by 42% due to the reduced volume of discarded material. A reduction in waste stream through recover the duff fraction using a water-only process, enhances fine coal production, while serving environmental, social, and governance (ESG) principles.

Modernising the mining life cycle through digital innovation: Automation considerations for hard rock mining. 'Man and machine collaboration is no longer avoidable', is how Professor Frederick Cawood began his presentation. 'Digitisation becomes valuable when we start to link outcomes of digital tools over the lifecycle of the mine and the mine lifecycle modernisation progresses when we start using data to progress from descriptive business intelligence systems toward predictive analytics, and lastly into automation and automated decisions.'

Three Technology Spotlights; RTIMS Programme under the Mandela Mining Precinct. Get Real facilitated by Jean-Jacques Verhaeghe, Programme Manager for the Real-Time Information Systems Programme (RTIMS) at Mandela Mining Precinct (MMP), Laser Technology – Make or break? facilitated by Zamambo Africa of the Council for Scientific Industrial Research (CSIR) and lastly, Safiya Turundu, Software Developer at CSIR Surface Resemblance Digital Twin by the Council for Scientific and Industrial Research (CSIR) .

Mining Technology for an Energy Transition, Mr. Tebogo Kale, Gravitas Minerals led panel the conversation between Ms. Lithakazi Nxiweni, Senior Consultant at Riis, Mr. Michael Combrink, Capital Sales Manager, Rham Equipment and Dr. Nelson Chipangamate, Researcher, Wits Mining Institute.

Interactive sessions encouraged the breaking of ground, sharing of insights and building strong networks.

The next three award winners were announced and invited on stage to participate in a discussion on thier experiences.

SKW Project Engineering's patented Werkman Mud Rush Chute is precision-engineered to SANS standards and underscores a commitment to zero harm within the mining industry. The double-door system ensures safety and efficiency, a small feeder door controls the regular flow of ore, while the larger safety door plays a critical role in emergencies, activating to provide an escape for operators during mud rush incidents while also serving as a barrier to prevent mud ingress into the tunnel.

The Nkangala Intelligent Face-Drill (IFD) patented Alignment System, uses 4 reference point sensors to align the drill to the rock face ensuring a 90-deg alignment to the face at all times, even on sloping faces allowing parallel drilling of subsequent holes. The drill accuracy ensures consistent particle size, resulting in improved removal operations, greater efficiency and cost saving. The automated features mean less-experienced operators can drill at a more predictable level.

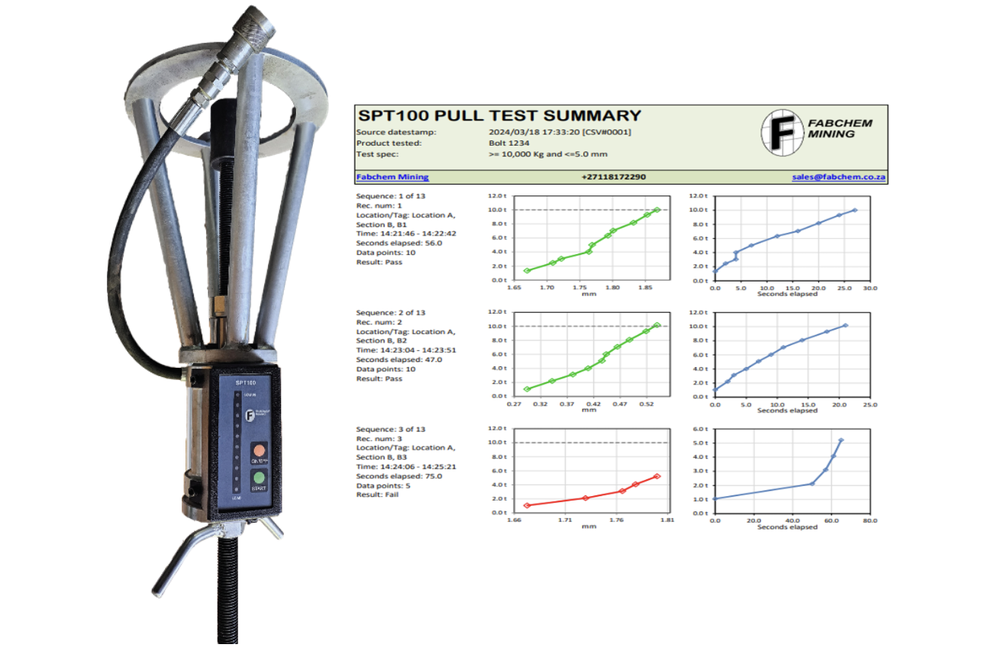

Fabchem's first of a kind SPT100 SMART Pull Tester for roof support digitises, eases and significantly speeds up the collection and reporting of pull testing on bolts and split-sets. Reports are created by Report Writer software, saving time and eliminating human error. It boasts electronic load & displacement sensors, ten load indication LED's, while data can be downloaded to a PC, smartphone or tablet. The software is compatible with Android hand-held (wifi) for real time reporting.

The Networking Lunch was provided by MEMSA member company Ditsogo Group a BBBEE Level 1, 100% black-female-owned steel engineering, fabrication and mining support company.

The afternoon session kicked off with panel discussion Funding Innovation. Moderated by Mr Matimba Mahange, CEO at JA Engineering, panelists included Alex Fenn, head of technology and innovation Sibanye Stillwater, Mr. Davis Cook, CEO of Riis, Freddy Mugeri, Group CEO Fabchem Mining and Dr. Rodney Managa, Senior Research Specialist HSRC.

Buraaq's Low Profile Drill Rig with significant safety enhancements has a minimum envelope size of 2mx2m, ISO compliant canopy structure and PLC-based platform. Programmable safety features include seatbelt and door interlocks & canopy warning alarm.

Digital pre-start procedure with operator verification, as well as data logging to track machine events. Additional safety features include a six-nozzle automatic fire suppression system. The rig is Level 9 ready.

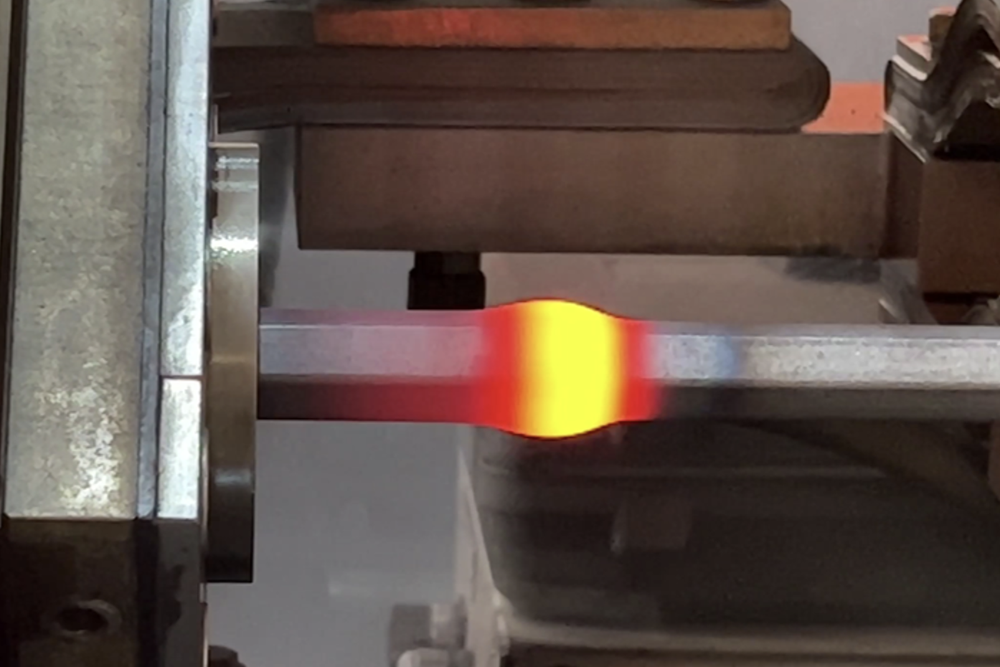

DaltronX 's patented Drill Steels surpass traditional rubber ferrules by reducing slippage and coolant leakage. Advanced electric upsetting manufacture processes, hexagonal cross-section and integrally formed collar ensure a precise chuck fit. The drill steels 'Bulb/Washer' ferrule and new Drill Depth Indicator endure 150% more force than competitors with superior durability to operational pressures, fewer failures, less downtime, cost savings, and a safer work environment.

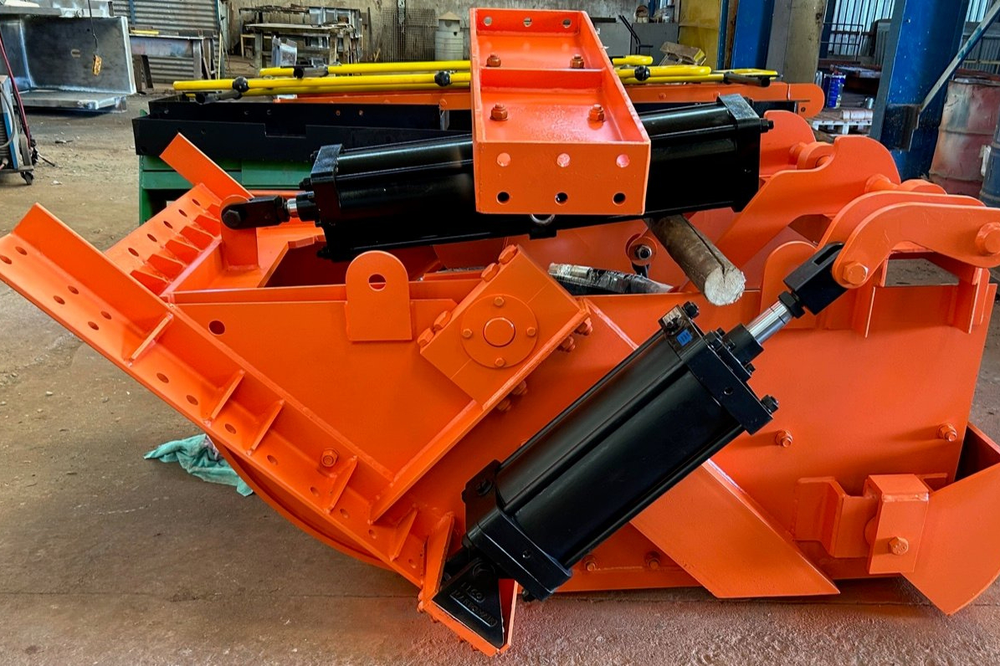

The Trackledon - Track Roller Manipulator is a patented, first of its kind dedicated track rolling and manipulating attachment, developed in collaboration with a global OEM. Its modular design can be attached to a forklift or fitted to the workshop floor allowing for the safe, remote controlled lifting of tracks. Also developed with a cable reeling attachment, it offers a safer, efficient and cost effective alternative for workshops.

The final panel discussion moderated by Dr Umeesha Naidoo, IDC Funding Innovation included panellists Ms. Bongi Ntsoelengoe, Executive Manager, Future Production: Mining, CSIR, Julie Courtnage, Executive Director at the Mandela Mining Precinct, Sietse van der Woude, Senior Executive: Modernisation and Safety at the Minerals Council of South Africa, Yusuf Timol, Director, Sectors Division, the dtic

In reviewing the conference and the awards to Julie Courtnage, the most valuable quality we need to develop as an industry is empathy, and the skill we most need to develop is active listening. Research development and innovation is about people, and the true value of the Mind Shift Conference is knowing that as a company you are not alone - engage, 'ask questions, they can be powerful force for change'.

By now we should recognise and acknowledge the uniqueness and diversity of our industry and that there is no one-size solution on offer. Keep it real, relevant and effective for Africa's rise.

Lastly, when it comes to collaboration, do it right from the start, do your homework, do the paperwork, as Louw Steyn of patent and legal firm Spoor & Fisher highlighted in his presentation, it could just be the difference between the good, the bad and the ugly.

For Sietse van der Woude there were three touchstones to come out of the conference and awards. Collaboration, commercialisation and contribution, the three C's.

The level of Collaboration, behind the award winning innovations was significant and the recognition was encouraging for the MCSA, a proud partner of the MMP that they were pivotal collaboration partners in the success of Digital Twin technology. Further collaboration was evident by OEM Machinery Contractors, winners of the Innovation in Surface Mining award who worked closely with Komatsu in response to the call by the OEM and mines, for a modular rolling and manipulating track attachment for their workshops which resulted in the development of the Trackledon, Track Roller Manipulator ™️. While Buraaq Mining Equipment, Innovation in Hard Rock Mining winners collaborated not only with the end user but internally as well, bringing their engineer on stage to share in the discussion and credit for his role in the development of their Low Profile Drill Rig. Simera Trace, winners of the award for Digital Solutions in Mining, developers of a digital ore identification and tracking system, have dedicated 15yrs of product development with Anglo for their innovation, proving tenacity and resilience are key attributes.

It is significant that only 10% of innovations reach Commercialisation. Gravitas Minerals, winners of the Collaboration in Mining award reiterated the challenge, and reward of self funding innovation and how for them they were driven by the purpose making the mines realise the potential and value in their dumps. Seed funding played a significant role in the successful innovation of the digital business case evaluation and tracking tool, including mine intelligence engine and sensor analytics application DX BC Tool by Digital Twin, who walked away with the Innovative Use of Data award.

The final C is Contribution, and this was evidenced in Simera Trace who not only focussed on their business metrics but also on local rural development. Gravitas Minerals who placed significance not only in the profit potential for their client of recycled waste dumps, but also in the benefits this poses to the environment. While Fabchem Mining awarded the accolade of Innovation Towards Zero Harm for their Smart Pull Tester boast significant productivity benefits for the mines, at the same time contributing to the safety of miner by eliminating the risk of human error when working with sensitive data.

Collaboration remains key, and MEMSA, a member-based cluster together with a wide range of innovation partners such as the Mandela Mining Precinct is helping to drive innovation and competitiveness in the local mining equipment manufacturing industry through activities such as the Mind Shift Conference and facilitating technology development partnerships.

MEMSA

Mining Equipment Manufacturers of South Africa (MEMSA), an industry cluster organisation established in 2016 with the support of the Department of Trade, Industry and Competition (dtic), advocates for and promotes the interests of its 60 members and the mining equipment manufacturing industry more broadly. It is MEMSA's vision to position local mining capital goods, components & product manufacturers as a cost competitive, innovative, and transformative industrial cluster which is the preferred supplier to the local, regional, and global markets. The cluster works to facilitate market access, technology development and cost efficiencies for members, and to help build a safe, sustainable, and competitive South African mining supply chain.

MEMSA Contact

Sue Breckenridge

Marketing & Communications Officer

Cell: +27 78 179 7342

Email: sue@memsa.org.za

Web: www.memsa.org.za

"Most inspiring platform and commendable tenacity and energy from the MEMSA team to build this continental value chain !", Hawie Viljoen, Trade Winds Capital.

"Thank you MEMSA and Mandela Mining Precinct for this honour. This only inspires me to do better with future projects and look for opportunities to collaborate with my friends in the mining industry", Bert Werkman, Werkman Engineering.

"Driving innovative and technology in the mining sector and convergence of brilliant minds", Mukesh Ramjee, IDC.

"I am incredibly honored to have delivered the opening keynote at the 2024 Mind Shift Conference, hosted by MEMSA. It was a truly enriching experience to kickstart the afternoon filled with insightful discussions. On stage, a panel of experienced innovators and engineers is captivating the audience with their session on "Putting our heads together: Collaboration for Innovation." Collaboration in driving forward technological and innovative advancements!" Professor Glen Nwaila, Wits Mining Institute.

"Well organised and facilitated event creating great networking opportunities", Louw Steyn, Spoor and Fisher.

"The conference was extremely informative and planned to perfection, well done!", Sayeeda Mayat, Buraaq Mining Services.

"An ideal for industry specific networking and stakeholder engagement", Leonard Lamola, Deputy Director, Department of Trade, Industry and Competition (dtic).

MEMSA wishes to thank our expert speakers and panelists and event sponsors including Old Mutual, GGDA, Ditsogo, Zevoli, OBPI Incubator, the CSIR, HPE, our media partner Creamer Media and awards sponsor Spoor and Fisher. As a member -based and member-funded organisation, your support is supremely appreciated.

In order to ensure an even better event next year, please remember to complete and return the event survey.